The IAM-ESS

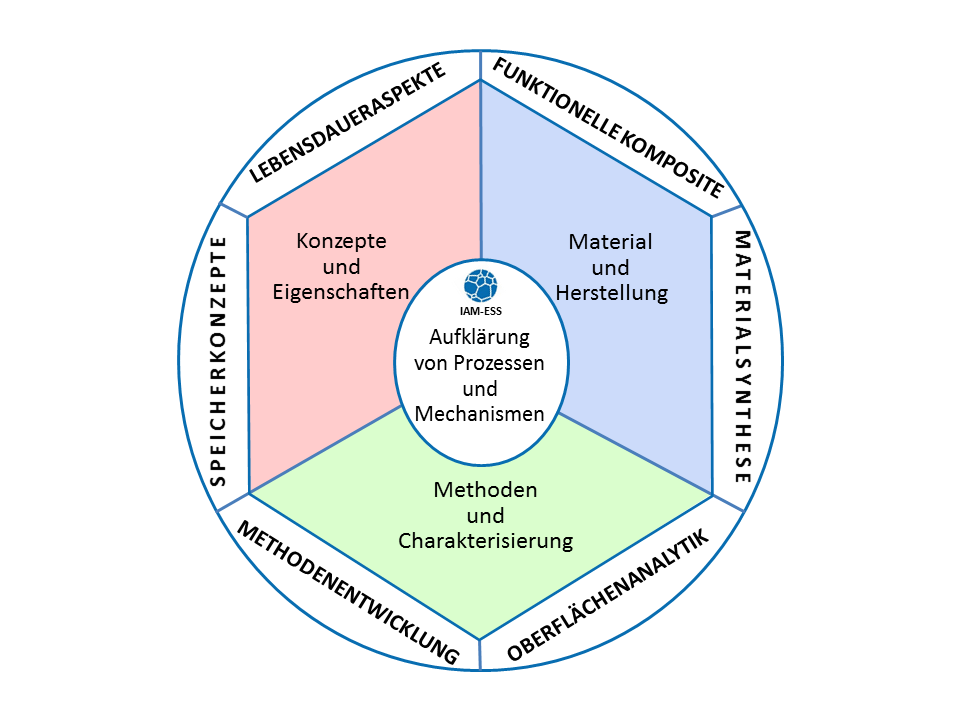

The Institute for Applied Materials - Energy Storage Systems at KIT deals with the production of novel materials for energy storage, such as for Li-ion batteries and post-lithium systems, as well as the research in the processes involved in energy storage, the manufacture and testing of electrodes and cells.

The institute is also part of the Institute for Inorganic Chemistry: Materials Research for Novel Energy Storage Systems (AK Ehrenberg).

In addition to the laboratory equipment required for research, the institute also has access to large scale research facilities such as neutron and synchrotron radiation sources. In cooperation with these facilities, the institute develops in-situ and in-operando techniques to investigate specific aspects in materials as well as complete, commercial devices.

To increase the efficiency of energy storage systems for applications in wind and solar energy or in the field of electromobility a long service life of storage systems is required. It is, therefore, important to study mechanisms of aging and degradation in order to develop lifespan models as accurate as possible. The investigations are carried out both, in-situ and post-mortem. Starting with the material analysis to setting up of models, the institute cooperates with partners from industry and other research institutes. Further points of interest of the institute are the development of new materials and storage systems, the investigation of so-called redox flow storage devices and the development of methods for the efficient investigation of entire components under in-operando conditions. The manufacture of electrodes and cells are also a part of research, as well as material development for fusion research.

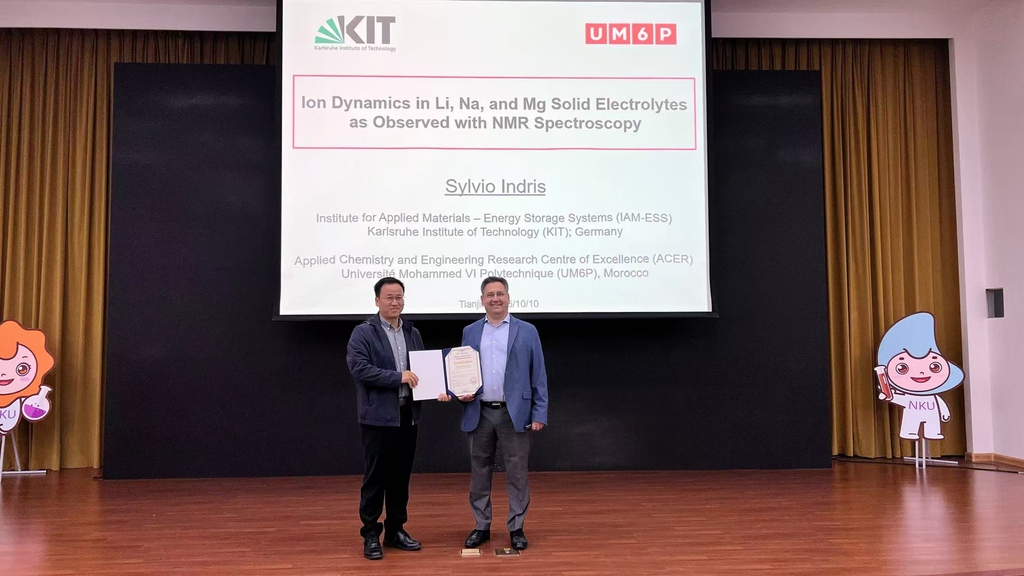

Sylvio Indris receives the Distinguished Lecture award at the eScience Summit Forum at Nankai University in Tianjin, China, on October 10, 2025.

The title of his lecture was “Ion Dynamics in Li, Na, and Mg Solid Electrolytes as Observed with NMR Spectroscopy”

For the second time, KIT (IAM-ESS) is proud to have hosted the Symposium on Direct Lithium Extraction on 9 – 10 October 2025. The event, which was directed by the scientific spokesperson, Dr. Fabian Jeschull, brought together leading experts from research and industry. The symposium, which spanned two days, covered the latest advancements in DLE technology, ranging from pioneering research to practical applications, with a focus on lithium extraction from salar and unconventional brines. With approximately 100 participants from both academic and industry backgrounds, the event provided a valuable opportunity to enhance collaboration between research and practice in this rapidly evolving field. Great thanks to the organization team: Fabian Jeschull, Martina Gamba, and Isabelle Südmeyer as well as the advisory board, Dr. Valentin Goldberg (BWG Geochemische Beratung GmbH, Germany) and Dr. Jonas Scottmann (University of Oslo, Norway) and to Laura Herrmann and Joscha Silas Fürniß from EnBW for hosting us at the Bruchsal geothermal power plant and DLE pilot.

Felix Bauer (IAM-ESS), a doctoral student from the Carbon-Based Materials working group, was awarded a poster prize for his work “Deciphering the Effect of Surface Oxygen Functionalities on Hard Hardbon” at the International Conference on Sodium Ion Batteries (ICNaB 2025) in Sydney.

The front cover of the current issue of Crystal Growth & Design shows a novel siloxane-bridged, dianionic linear Co(II)₃ complex. Due to the ferromagnetically coupled Co moments, this single-molecule magnet exhibits a comparatively slow magnetic relaxation. The experimental results and theoretical calculations were performed by a scientist from IAM-ESS in collaboration with scientists from the Indian Institute of Technology Madras and the National University of Singapore and are published as an article in Crystal Growth & Design (Volume 25/Issue 17).

Link zu Front Cover:

Prof. Dr. Siegbert Schmid receives the International Excellence Fellowship from the Karlsruhe Institute of Technology (KIT). Prof. Schmid is currently a professor at the University of Sydney and will be completing his stay at the Institute for Applied Materials – Energy Storage Systems (IAM-ESS) at KIT under the direction of Prof. Dr. Helmut Ehrenberg, who is also POLiS spokesperson and principal investigator.

Während des Upcell Alliance Events in Barcelona on June 27, Noah Keim received the “2025 Upcell Young Scientist Award” for his doctoral thesis. This award recognizes the best dissertation related to batteries. Noah Keim from IAM-ESS focused his work on the processing of environmentally friendly binders that can be processed in an aqueous medium.

Solid State Ionics conference in London (July 15-19, 2024):

Prof. John Kilner (President of the Solid State Ionics Society) gives the poster award certificate to Dr. Mareen Schaller for her poster “Ion dynamics of multicationic substituted High-Entropy Argyrodite Superionic Conductors”.

Link zur Konferenz

The annual POLiS Conclave took place from June 23 to 23, 2025 in the heart of Karlsruhe. Around 130 scientists from Karlsruhe Institute of Technology, Ulm University and Justus Liebig University Giessen as well as international guest scientists met for two days to discuss the latest research trends in battery research and get an insight into the second funding period of the Cluster.

The agenda featured a total of 5 keynote presentations, 25 regular talks and three poster sessions, in which a total of over 50 POLiS members presented their research findings. Also this year, a poster prize was awarded, voted for by the participants.

The joint battery research network POLiS (Post Lithium Storage) has prevailed in the competition and remains a cluster of excellence. POLiS scientists have been conducting research into innovative battery materials and storage technologies since 2018. In the upcoming funding period from 2026 to 2032, the researchers will focus on the realisation of full cells and the interactions between the battery components along the entire cell. In the "Post Lithium Storage" cluster of excellence at KIT, the University of Giessen and Ulm University, which was approved initially in 2018, scientists – among these Prof. Helmut Ehrenberg, Prof. Anass Benayad, Prof. Daria Mikhailova, Dr. Fabian Jeschull and Dr. Anna Smith from IAM-ESS - are researching pioneering solutions for electrochemical energy storage (EES). The aim is to develop lithium-free batteries that are safe, powerful and sustainable. Further cooperation partners are the Centre of Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) and Helmholtz Zentrum Berlin (HZB).

Researchers from IAM-ESS (Dr. Michael Knapp, Dr. Sylvio Indris, Dr. Valeriu Mereacre) had the honor of welcoming António Costa, President of the European Council, during their research stay for a series of measurements at the ALBA Synchrotron.

Accompanied by Núria Montserrat, Consellera de Recerca i Universitats; Javier Selva, Director General for Knowledge Transfer; and Caterina Biscari, Director of ALBA, President Costa toured the facilities and learned about our mission: to train and promote talent, offer high-quality services to users worldwide, and advance cutting-edge research throughout Europe. The visit highlights the crucial role of large research infrastructures such as ALBA in promoting scientific excellence, collaboration, and competitiveness in Europe.

Link

Dr. Daria Mikhailova has recently joined Karlsruhe Institute of Technology (KIT) as professor for “Materials for Sustainable Electronic Energy Storage” at the Institute for Applied material – Energy Storage Systems (IAM-ESS). During his career before his arrival to KIT, she was Group Leader at Max-Planck Institute for hemical Physics of Solids (MPI CPfS), Dresden / Germany and of the Electrochemical Energy Storage group at IFW Dresden. The focus of her research group is on electrode materials for sodium and magnesium batteries. Watch the video to find out more on her reseach.

Around 25 researchers from the POLiS Cluster of Excellence and the Graduate School Electrochemical Energy Storage (GS-EES) – including IAM-ESS colleagues - had the great opportunity to visit the Center for Solar Energy and Hydrogen Research (ZSW) in Ulm - a key player in applied battery research and technology transfer in Germany.

Since April 2025, Dr. Anass Benayad has been assigned as professor for ´interfacial processes´ at the Institute for Applied material – Energy Storage Systems (IAM-ESS). During his career before his arrival to KIT, he was senior researcher at Samsung Advanced Institute of technology (SAIT) from 2006 to 2013 in South Korea, then Director of research at the French Atomic Energy Commission in the department of innovation for renewable energies and nanomaterial (CEA-Liten) from 2013 to 2025. He was in charge of surface characterization center at the platform of nano-characterization (PFNC). His research focusses on the investigation of the behavior of ions and electrons at the various interfaces within battery materials developing operando photoemission spectroscopy.

The project “Sodium-Ion-Battery Germany Research – SIB:DE FORSCHUNG,” funded by the Federal Ministry of Education and Research (BMBF), aims to evaluate the suitability of sodium-ion battery technology (SIB) for the European energy and mobility transition and to achieve rapid industrial implementation. To this end, 21 national partners from science and industry are pooling their expertise, from battery material development to the manufacture of large-format cells, in order to enable the rapid transfer of research results into practical application.