Electrode Development for Lithium Ion Batteries

|

Materials

|

|

Process Technology

|

|

Products

|

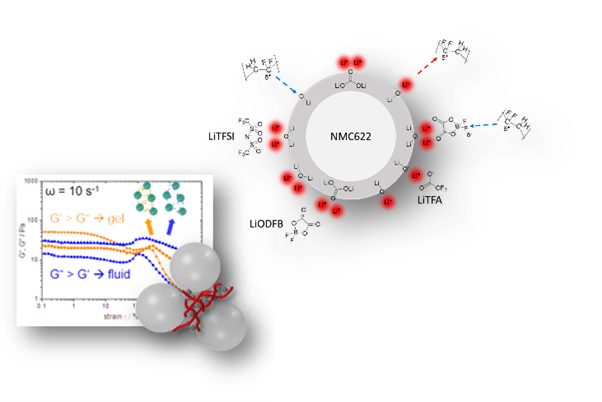

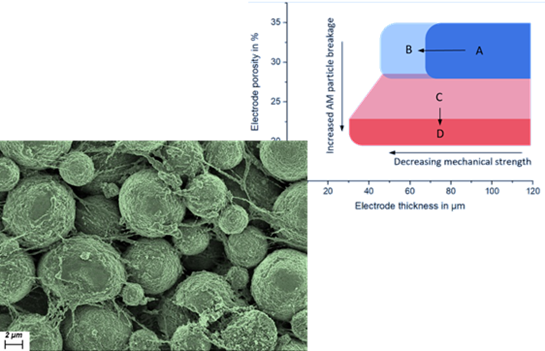

To realize the full potential of batteries, it is important to consider not only the active materials used, but also the other electrode components and their processing. The inactive components added to improve the conductivity and mechanical properties of the electrodes also play an important role. Binders and conductivity additives are therefore at the forefront of electrode development, with a particular focus on their interactions and influence on the active material and cell properties.

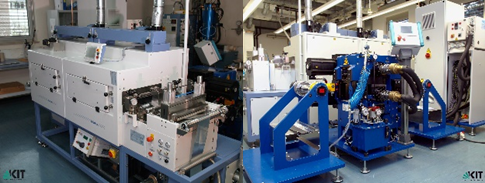

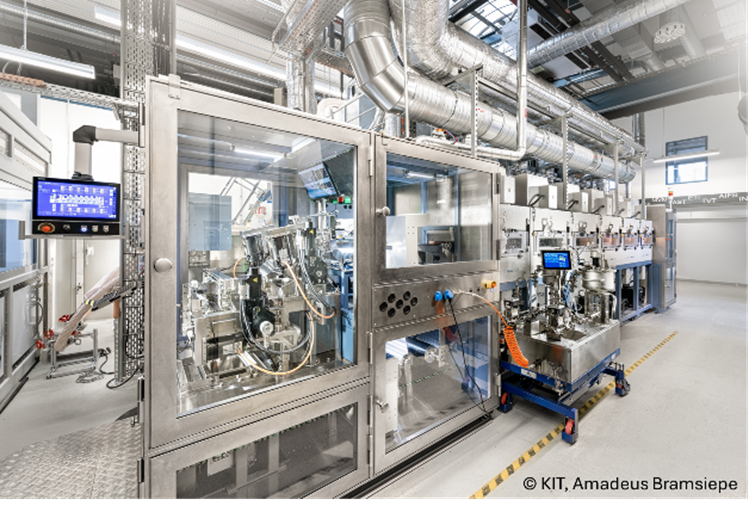

High performance mixers and roll-to-roll coating machines are available to produce slurries and electrodes, covering the full range from laboratory scale to pilot production.

Research Activities

|

Aqueous Processing of Electrodes

|

|

Homogeneity and Stability of Slurries

|

|

Dry Coating of Cathodes

|

|

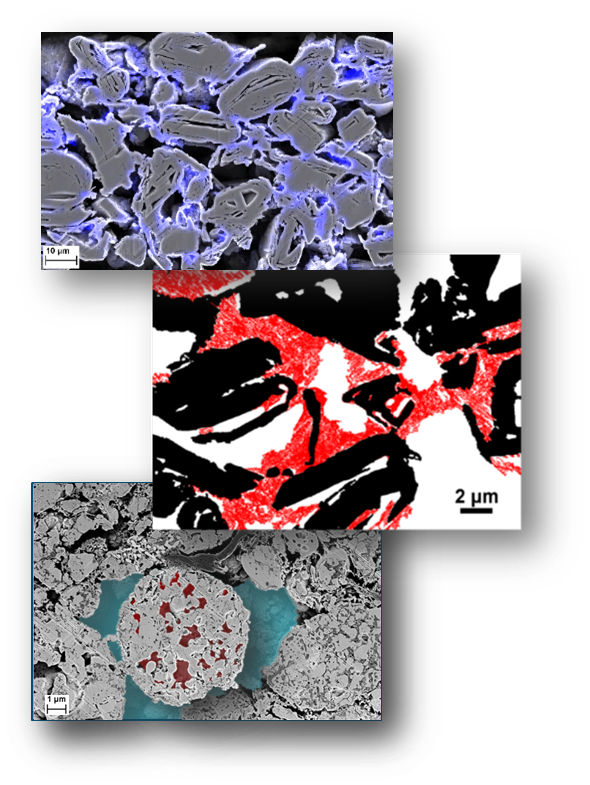

Investigation of Electrode Structure

|

Electrode Manufacturing of Laboratory Pouch Cells

|

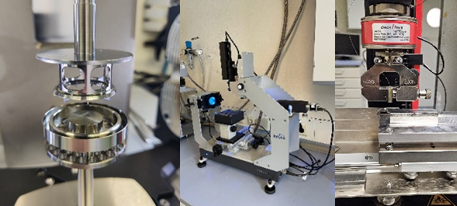

Laboratory Equipment

|

|

Pilot Plant Facilities

Dry mixer and multi roll calender for dry coating of electrodes in a microenvironment at dew point -50 °C |

|

Electrode Specific Characterization

Test facilities for coin cells and laboratory pouch cells with more than 200 channels |