Creep behavior and deformation mechanisms of precipitation-strengthened Ta-Mo-Cr-Ti-Al alloys

Motivation

Refractory high-entropy alloys (RHEAs) and refractory complex concentrated alloys (RCCAs) consisting of a combination of high melting point, passivating and light elements are a promising new material group which have shown excellent high temperature properties (e.g. high strength and resistance to oxidation). However, creep resistance that is even the most important requirements for structural materials applications at high temperature has only fragment results.

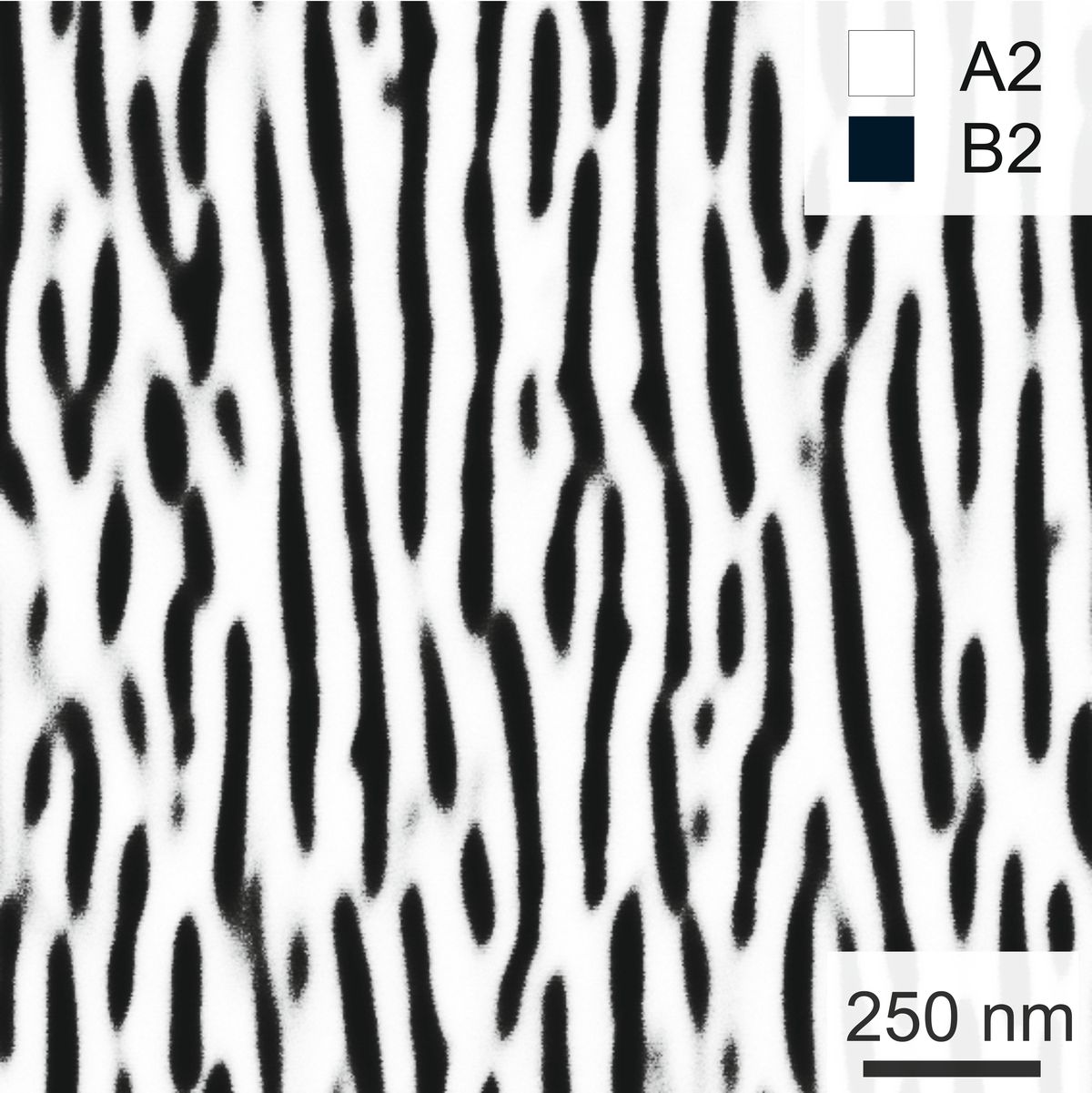

As we all know, the two-phase microstructure of classical Ni-based superalloys provide the excellent creep resistance at high temperatures for gas turbine applications. Unfortunately, their limited melting point (approx. 1450°C) restricts the service temperature range. Promisingly, most of RHEAs and RCCAs (e.g. Ta-Mo-Cr-Ti-Al) with higher melting points have shown the analogous two-phase microstructure which can dominant the service temperature by the precipitation-strengthened. Therefore, we focus on the compression creep behavior of Ta-Mo-Cr-Ti-Al alloy in our study. This alloy has shown a promising creep resistance even at high temperatures very close to its solvus temperature. And a similar rafting microstructure as that of Ni-based superalloys has been observed in certain grain direction after creep deformation.

Objectives

- Ta-Mo-Cr-Ti-Al alloys with two different Al contents

- Appropriate heat treatments are used to obtain the two-phase microstructure

- Assessment of high temperature creep resistance by means of reproducible characteristic values

- Understanding the creep deformation behavior and precipitation-strengthening mechanisms of the RCCAs

Investigations

- Evaluating alloy quality by O/N analysis to investigate material purity and identifing alloy composition precisely by chemical analyses

- Determining creep properties by varying temperature and stress for the creep tests

- Investigating microstructure after heat treatments and creep deformation by means of microscopic characterization (e.g. SEM, TEM, APT)

Funding

Chinese Scholarship Council