Holistic qualification of copper for the binder jetting process with targeted porosity adjustment based on heat exchangers for electromobility

Motivation

Heat exchangers are a crucial component in almost all engineering systems. The development of smaller and more complex engineering applications entails the development of more complex and efficient heat exchanger systems. The production of these heat exchanger systems through conventional casting and subtractive manufacturing methods become increasingly difficult as complexity of the systems increase.

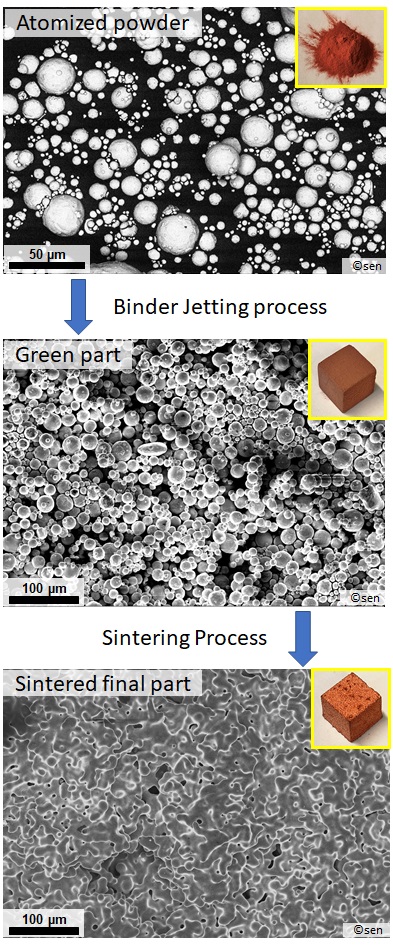

Additive manufacturing (AM) provides new possibilities in the synthesis of complex heat exchangers. In this project, in close collaboration between KIT and industry, Cu based heat exchangers are synthesized via the binder jetting AM process and studied in terms of structural stability and heat conductivity. Unlike the other AM process like selective laser melting or laser powder bed fusion, the binder jetting process enables a careful control over the porosity as well as the morphology of the mesostructures formed in the final AM produced heat exchangers.

Objectives

Stage 1:

Pure Cu powders are synthesized via atomization by our industry partners. These Cu powders are atomized with a passivation layer of Cu oxides. At IAM-WK, in the first stage of the project, we characterize various batches of these powders at the micro and nano level. The goal is to identify the best powder suitable for the binder jetting process from the various batches of powders produces by the industry partners. The different powder batches are analyses and classified, in terms of:

- Particle morphology,

- Particle size distribution,

- Crystal structure,

- Level of particle agglomeration,

- Hollowness of particles,

- Chemical characterization: content of oxygen/nitrogen/Carbon in the powders

Stage 2:

The analyzed powders are additively manufactures using the binder jetting process in one of our partner institutes (WBK) at KIT. After de-binding and sintering of the parts produced by binder jetting will be analyzed similar to stage

- Chemical characterization: to quantify the process induced contamination of carbon/nitrogen/oxygen

- Microstructural changes due to the sintering process

- Analysis of the mesostructures achieved in terms of morphology, porosity and heat conductivity

The combined goal of the 2 stages is to correlate and connect the characteristics of the Cu powders, with the different parameters of the binder jetting and sintering processes and ultimately with final mesostructures in terms of their morphology and heat exchange performance.

Investigations

- Scanning electron microscopy for determination of particle size and level of agglomeration of powders as well as imaging the finished parts

- X-Ray Diffraction (XRD) for determination of crystal structure

- Chemical analysis via Hot Carrier Gas Extraction (HGCE) and Combustion Analysis (CA)

- Determination of thickness and composition of the oxide passivation layer by Focused Ion Beam (FIB) milling and Atom Probe Tomography (APT) at the nano level

Funding

Innovation Campus Future Mobility (ICM)