Material development for additive manufacturing

Fused Filament Fabrication (FFF), also known as Fused Deposition Modeling (FDM), is a method of additive manufacturing for the production of components, models and prototypes, which are built up layer by layer from meltable plastic. The most common materials are listed on the page for commercial materials.

At the IAM-WK, this approach was adapted to the replication of ceramic and metallic components. The process chain required for this includes the development of ceramic and metallic molding compounds for the production of filaments, the 3D printing of green parts and the subsequent heat treatment (debinding and sintering).The scalability and production of complex components with individual dimensions can be adjusted depending on the molding compound composition (ratio of powder to binder system) and the nozzle diameter used.

In addition to molding compounds for the production of pure ceramics and metals, powder-plastic mixtures are also developed that are not thermally post-treated.

Material development

These feedstocks consist of at least 50 vol% solids in the case of ceramic-containing molding compounds and at least 60 vol% solids in the case of metal-containing molding compounds. This simplifies the compaction of the structure during sintering and minimizes shrinkage and distortion of the components. The remaining volume consists of (usually) at least three different polymers:

- Dispersant (D): Supports the breaking up of the powder agglomerates and thereby lowers the viscosity of the feedstock.

- Scaffold polymer (GP): Ensures the stability of the component after molding and the first debinding step.

Generally consists of long polymer chains (high molecular weight) and therefore only softens at high temperatures and is then highly viscous.

-

Base polymer (BP):Generally has a low molecular weight, softens at lower temperatures and is less viscous than the BP.Due to the short molecular chains, the component is mechanically not very dimensionally stable, which is why GP and BP are usually mixed. This allows the advantages of both polymers to be utilized

Process chain

The process chain is based on that of powder injection molding and has been expanded to include filament extrusion.

The feedstock is mixed in one of our measuring kneaders. The process is discontinuous and very homogeneous mixtures can be produced in small quantities, which is ideal for material screening and material development. In addition, the torque is recorded during the process, which is an initial indication of the quality and processability of the feedstock. Very large quantities can be produced in our twin-screw extruder. The rheological characterization after mixing is carried out in the high-pressure capillary rheometer.

The Noztek pro extruder (Noztek, Shoreham, UK) is used to produce the filaments. This allows extrusion of filaments with a diameter of 1.75 mm as well as 3.0 mm.

The 3D printing takes place in one of our modified printers. They are exclusively open systems in which the printing parameters can be specially adapted to the materials and optimized for the component geometries.

Post-processing includes two-stage debinding (solvent and thermal), during which first the base polymer is dissolved and opens up pore channels for the subsequent thermal decomposition of the scaffold polymer. The final process, sintering, is carried out with oxide ceramics in a chamber furnace under a normal atmosphere. With metals, it takes place in special sintering furnaces under vacuum or inert gas. The sintering process is always associated with shrinkage, which is taken into account in advance during print preparation.

Alumina

The most commonly used high-performance ceramic material is aluminum oxide (Al2O3), also known as "alumina" or, as a single crystal, "corundum". With increasing purity, it is electrically insulating, hard and wear-resistant with good sliding properties in corrosive media and at high temperatures. It is chemically and thermally stable, biologically inert and can be produced translucent.

We would like to thank the DFG for making this work possible!

Zirconia

Zirconium oxide (zirconium(IV) oxide, ZrO2) is also widely applicable. In order to prevent large volume jumps in the crystallites due to phase transformation during sintering, the lattice is partially or fully stabilized by doping in the high-temperature modifications. This gives the ceramic high strength and very high resistance to the propagation of cracks. Due to its good biocompatibility and translucency, which can be adjusted by doping, zirconium oxide is already used as a dental prosthesis. In addition, Y-doped ZrO2 conducts oxygen ions, which is utilized in lambda sensors and fuel cells.

We would like to thank HEiKA for making this work possible!

Publication list sintered ceramics

Roser, C. J.; Erber, R.; Zenthöfer, A.; Rues, S.; Lux, C. J.; Nötzel, D.; Eickhoff, R.; Hanemann, T.

2025. Journal of Functional Biomaterials, 16 (11), Article no: 397. doi:10.3390/jfb16110397

Eickhoff, R.; Nötzel, D.; Oral, G.; Scholz, M.; Hanemann, T.

2025. Materials & Design, 254, 114148. doi:10.1016/j.matdes.2025.114148

Eickhoff, R.; Antusch, S.; Nötzel, D.; Hanemann, T.

2025. Materials & Design, 254, 114088. doi:10.1016/j.matdes.2025.114088

Nötzel, D.

2023. Albert-Ludwigs-Universität Freiburg im Breisgau. doi:10.6094/UNIFR/233835

Nötzel, D.; Eickhoff, R.; Pfeifer, C.; Hanemann, T.

2021. Materials, 14 (19), Art.-Nr.: 5467. doi:10.3390/ma14195467

Eickenscheidt, M.; Langenmair, M.; Dbouk, A.; Nötzel, D.; Hanemann, T.; Stieglitz, T.

2021. Materials, 14 (1), Art. Nr.: 200. doi:10.3390/ma14010200

Nötzel, D.; Hanemann, T.

2020. Materials, 13 (19), Art.-Nr.: 4461. doi:10.3390/ma13194461

Nötzel, D.; Hanemann, T.; Eickhoff, R.

2019. Keramische Zeitschrift, 71 (6), 56–61. doi:10.1007/s42410-019-0074-7

Nötzel, D.; Eickhoff, R.; Hanemann, T.

2018. Materials, 11 (8), 1463–1473. doi:10.3390/ma11081463

Titanium alloy Ti6Al4V

This alloy with 6 wt% aluminum and 4 wt% vanadium is the most commonly used titanium alloy. It is characterized by a low density (approx. 4.4 g·cm-3) combined with high strength. The alloy was originally developed for use in the aerospace industry, but is also approved for medical applications such as implants. The reasons for this are its high biocompatibility, corrosion resistance and lack of magnetism.

Our feedstocks can be used to print very large components, such as hip implants, very small bodies, such as dental implants, or very delicate components.

Alloy CoCrMo F75

Due to its good biocompatibility and high corrosion resistance, this cobalt-based alloy is used as an implant material. It is used as a joint replacement due to its high wear and fatigue resistance and the ability to polish the components to a mirror finish. However, it is also widely used in the dental industry as it can be cast without a protective atmosphere and veneered very well with ceramic materials.

Tungsten

This very refractory metal is or was present in every household in the form of the filament in light bulbs. It is highly resistant to corrosion and can shield radiation better than lead due to its high density (approx. 19.3 g·cm-3). However, it is not used as often for this purpose due to its high price and difficulty in processing. The complex processability of tungsten is due to its melting point of 3422 °C and its high brittleness even with low impurities. It is therefore shaped as a powder with a subsequent sintering process.

In addition to 3D printing the material, we are also developing the process control of tungsten powder in an EBM (Electron Beam Melting) system, which is also one of the methods of 3D printing.

S. Antusch: Need a tricky tungsten piece? Print it!(Fusion in Europe 1/2018 (2018))

Copper

What would today's world be without copper? Mainly due to its excellent electrical conductivity, but also due to its good thermal conductivity, the metal is used in almost every electronic circuit, power lines, electric motors and heat exchangers or heat sinks.

Publication list metals

Eickhoff, R.; Antusch, S.; Nötzel, D.; Hanemann, T.

2025. Materials & Design, 254, 114088. doi:10.1016/j.matdes.2025.114088

Eickhoff, R.; Hanemann, T.; Nötzel, D.; Antusch, S.

2025. doi:10.17632/bkzgpb64y6.1

Eickhoff, R.; Antusch, S.; Nötzel, D.; Probst, M.; Hanemann, T.

2024. Polymers, 16 (17), Art.-Nr.: 2548. doi:10.3390/polym16172548

Eickhoff, R.; Antusch, S.; Nötzel, D.; Hanemann, T.

2023. Materials, 16 (8), Art.-Nr.: 3162. doi:10.3390/ma16083162

Eickhoff, R.; Antusch, S.; Baumgärtner, S.; Nötzel, D.; Hanemann, T.

2022. Materials, 15 (18), Art.-Nr.: 6442. doi:10.3390/ma15186442

Printed battery materials

As part of the POLiS (Post Lithium Storage) Cluster of Excellence, 3D printing materials for solid-state batteries are being developed based on the transport of Na2+ ions. This topic combines our expertise in the development of electrolyte systems and material development in 3D printing.

The goals are to increase safety through flame-retardant electrolytes and new opportunities for battery construction and optimization of volume through the design freedom of 3D printing.

Publication list Polymer printed battery materials

Kutlu, A. C.; Nötzel, D.; Hofmann, A.; Ziebert, C.; Seifert, H. J.; Mohsin, I. U.

2024. Electrochimica Acta, 503, Art.-Nr.: 144881. doi:10.1016/j.electacta.2024.144881

Kutlu, A. C.; Nötzel, D.; Ziebert, C.; Seifert, H. J.; Ul Mohsin, I.

2024. Batteries & Supercaps, 7 (1), Art.-Nr.: e202300577. doi:10.1002/batt.202300577

Kutlu, A. C.; Nötzel, D.; Ziebert, C.; Seifert, H. J.; Mohsin, I. U.

2024. Batteries & Supercaps, 7 (1), e202300357. doi:10.1002/batt.202300357

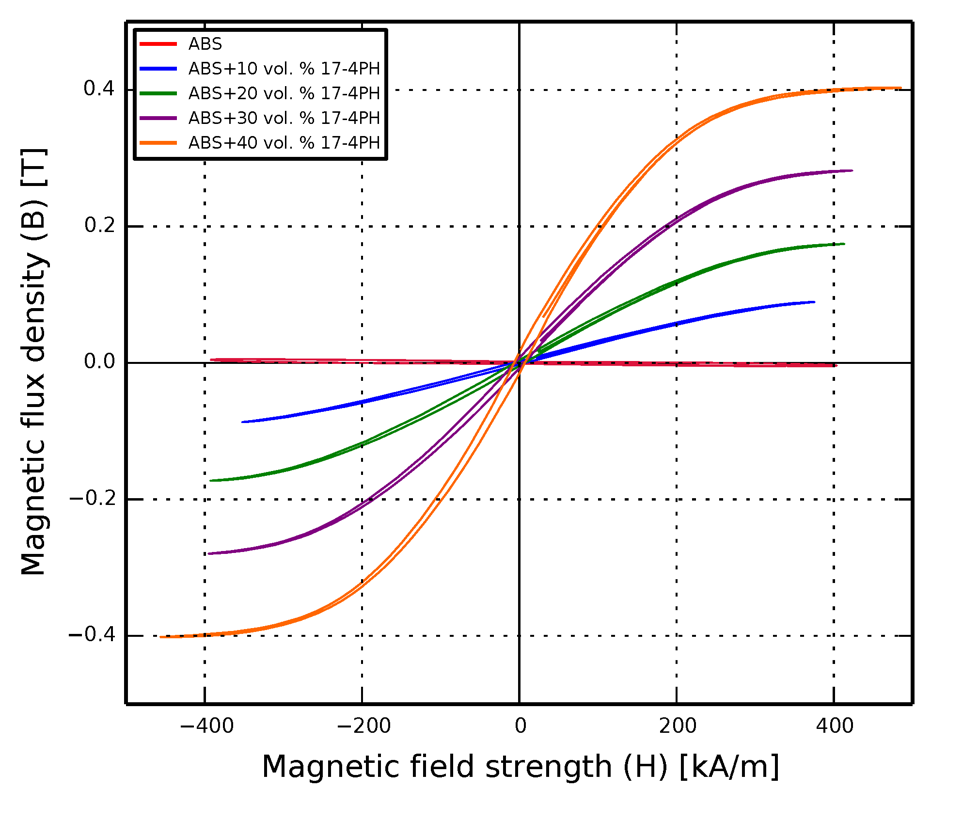

Polymer matrix composites

It is not always necessary to produce pure ceramics or metals in order to obtain materials with desired properties. Even a medium filling (20 - 40 vol%) with particles can be sufficient to increase thermal conductivity, to obtain electrical conductivity or magnetism or to improve the dielectric properties of a polymer. The strength of the properties depends on the content of the filling material.

If you have any questions, please contact Dr. Ing. Dorit Nötzel