Small scale deformation and failure of Mo-Si-Ti

Motivation

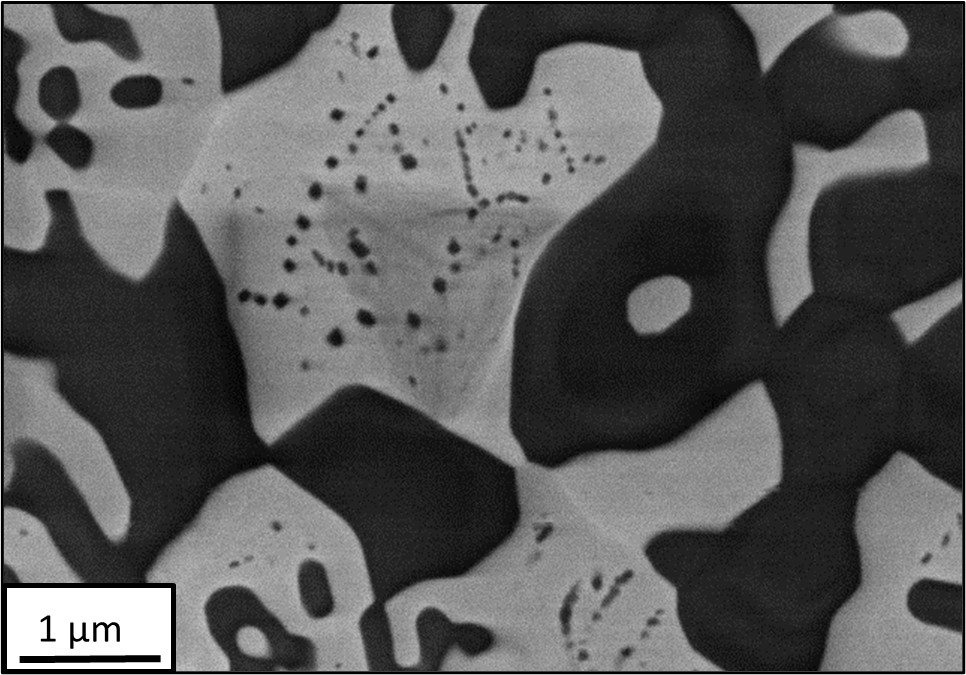

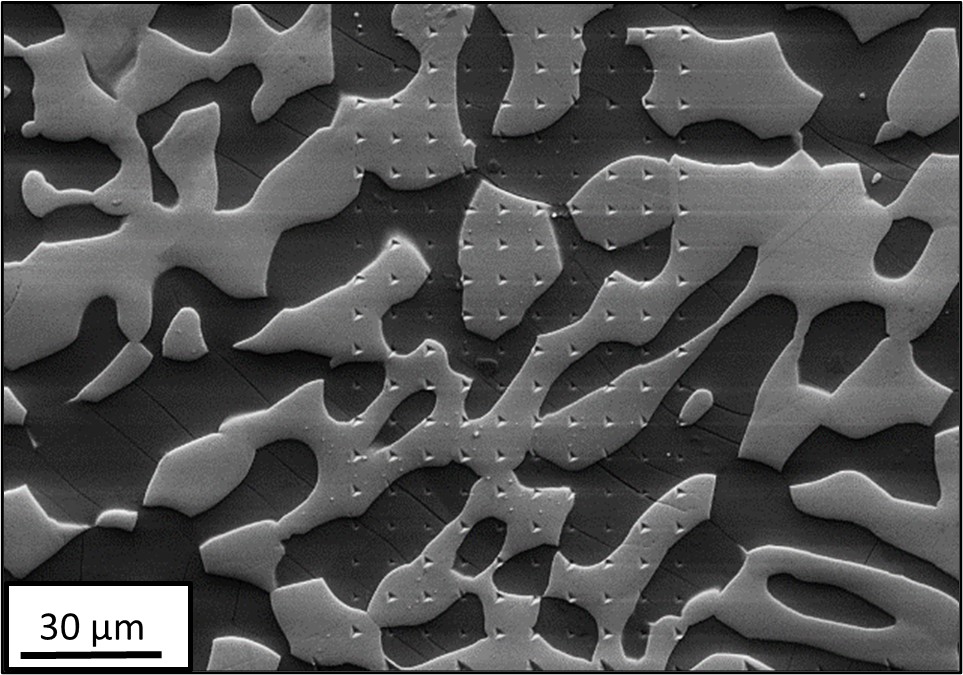

Mo-Si-Ti alloys, notably the eutectic composition Mo-20Si-52.8Ti (at%), have garnered significant attention due to their remarkable resistance to oxidation and creep. However, their practical use is currently constrained by their limited ductility at room temperature and a brittle-to-ductile transition occurring at around 1100 °C. This composition consists of a body-centered cubic (BCC) disordered Mo-rich solid solution and an intermetallic hexagonal (Ti,Mo)5Si3. Therefore, a thorough comprehension of the deformation behavior of the individual phases is crucial for understanding the reason for the inherent brittleness of the material. This understanding provides guidelines for improving ductility of the alloy.

In this project, the deformation mechanisms are investigated experimentally by performing micromechanical testing. The testing such as nanoindentation, micropillar compression with and without phase boundary and/or microcantilever bending is performed aiming to comprehend the mechanical behavior of the individual phases and their interfaces.

Additional factors such as local elemental concentration, presence of interstitials and precipitates and the orientation of the individual phases with respect to the testing direction can affect the strengthening of the material and have to be investigated. This gives indications about the contribution of the individual phases to the strength of the system and aids in understanding the overall mechanical behavior.

Objectives

- Determination of the main dislocation mechanism controlling the strength in (Mo,Si,Ti)SS

- Identification of the role of the interface and its contribution to the strength of the two-phase alloy

- Investigation of the strain transfer across the interface and the fracture toughness of the individual phases

Methodology

Micromechanical characterization

- Statistical nanoindentation to isolate the hardness and indentation modulus of the individual phases

- Micropillar compression and micro-cantilever bending tests testing to determine the mechanical response of the individual phases and mechanical property such as toughness and strength at the interface

Chemical and structural characterization

- ICP-OES and SEM-EDX to determine the composition and local concentration of the elements

- HCGE to determine the interstitial dissolved elements

Microstructural characterization

- SEM-EBSD to determine the microstructure and local crystal orientation with the base microstructure

Funding

Graduate school 2561 "Materials Compounds from Composite Materials" by Deutsche Forschungsgemeinschaft