Multiscale mechanical characterization and modelling of deformation mechanisms in refractory metal solid solutions

Motivation

The need for alloys in highly specialized applications requires more and more elaborate alloy compositions. Simultaneously, due to the development of high-entropy alloys, the number of possible alloy compositions increased also significantly. To design alloys for targeted applications, a comprehensive theoretical understanding of compositionally dependent properties is required.

This project combines experimental and modelling approaches to gain fundamental insights into the deformation mechanisms in refractory metal solid solutions. The impact of solute concentrations on the mechanical properties is thoroughly assessed by mechanical testing across several length scales and compared to the results of state-of-the-art modelling.

One focus is the evaluation of solid solution strengthening and its impact on dislocation motion: In contrast to established models for body-centered cubic alloys, recent results in high-entropy alloys indicate a significant contribution of edge dislocation motion to yielding. This phenomenon was investigated systematically in binary Mo-based solid solutions with reduced chemical complexity. Solid solution strengthening was isolated by combining scale-bridging mechanical characterization and chemical analyses methods. The comparison to available models in literature allowed to highlight the significance of edge dislocation motion also in these binary, body-centered cubic alloys.

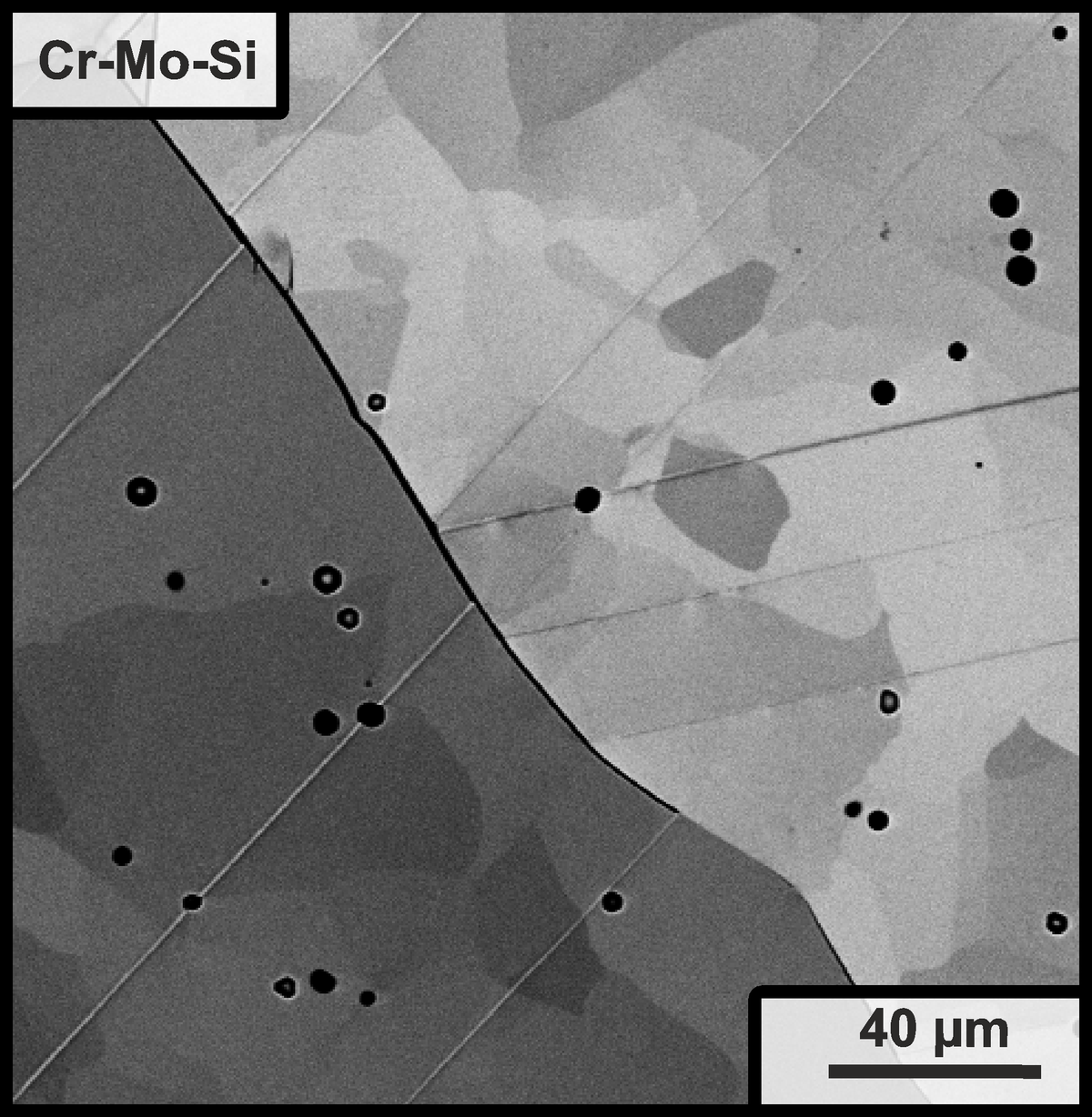

In Cr-based solid solutions, twin formation is observed up to high temperatures, leading to a continuous grain refinement during deformation and, thus, high work-hardening capabilities of these solid solutions. In combination with an outstanding oxidation resistance compared to other refractory metal alloys, these alloys show a promising profile for future high-temperature applications. To tailor the mechanical properties to these applications, a thorough understanding of the complex interplay between dislocation slip and twin formation, in conjunction with varying grain sizes and solute concentration is investigated.

Objectives

- Systematic, experimental assessment of relevant strength contributions in refractory metal solid solutions

- Correlation of the resulting yield strength to available models for body-centered cubic alloys to identify relevant contributions of different deformation mechanisms

- Generalization of the findings to body-centered cubic solid solutions of arbitrary compositions to improve modelling predictions for a guided alloy design

Methods

Mechanical characterization from the nanoscale to the macroscale:

- Nanoindentation to assess hardness and elastic properties irrespective of grain boundary effects

- Vickers hardness testing to correlate the nanoindentation measurement to macroscopic data

- Compression testing to assess the yield strength of the alloys as average across grain orientations

Chemical and structural characterization of the solid solutions:

- SEM and EDS to assess microstructure and composition

- XRD to verify the crystal structure

- APT, HCGE and ICP-OES to identify interstitial and substitutional element contents

Data processing and yield strength analysis according to strengthening models

- Automated processing of experimental data

- Large throughput statistical analysis

- Modelling of strength contributions according to the Maresca-Curtin and Suzuki-Rao models for solid solution strengthening in body-centered cubic alloys

Funding

Graduate school 2561 "Materials Compounds from Composite Materials" by Deutsche Forschungsgemeinschaft