Defects in Materials

The "Defects in Materials" group investigates the defect structure and its impact on thermodynamics, kinetics and mechanical properties of crystalline materials. The group is both settled at Campus South and Campus North of the KIT.

Head of the group

Research associates

M.Sc. Giorgia Guardi

M.Sc. Johannes Wild

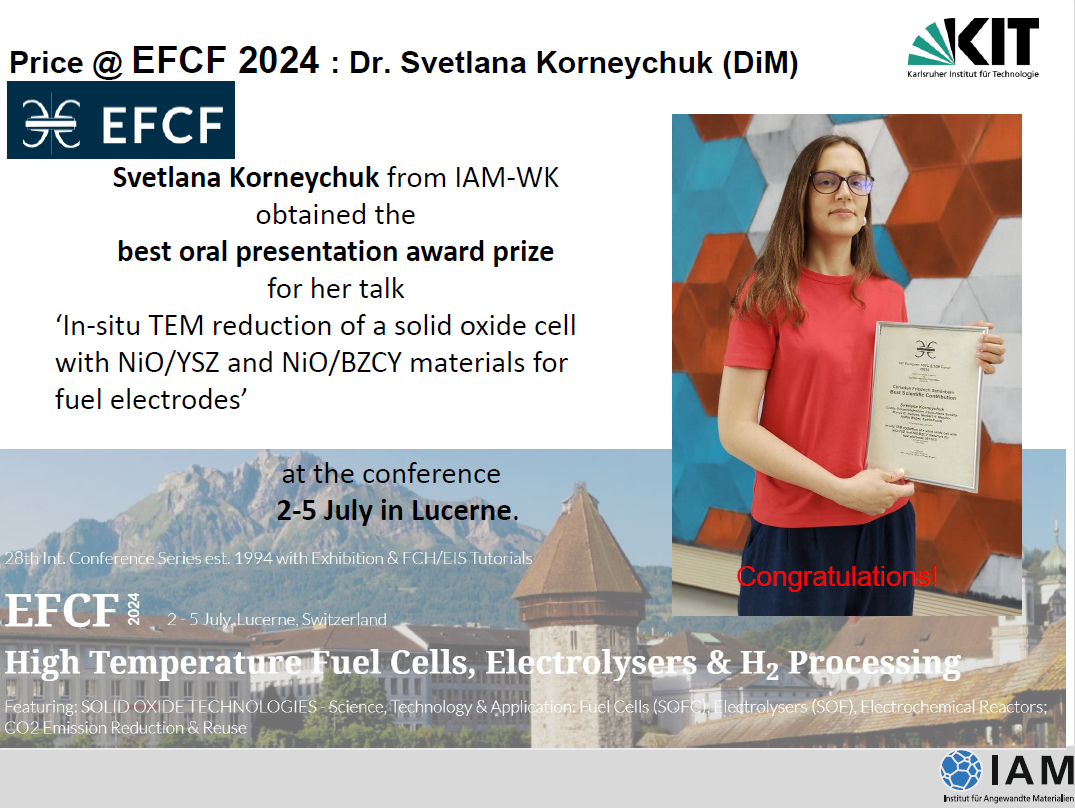

Dr. Svetlana Korneychuk

M.Sc. Ingrit Nurak

M.Sc. Gabriele Palazzo

M.Sc. Kai Lagemann

M.Sc. Magdalena Seiler

Our work is supported by

Dr. Dorothée Vinga Szabó

Dr. Sabine Schlabach

in the frame of KNMF und des MTET.

Core expertise

Owing to the complexity of their interactions, defects in crystalline materials can strengthen materials properties, but they can also impose detrimental effects. The defect structure of materials is related to the specific manufacturing processes and the process management, and hence it can be adjusted by selecting desired process conditions. In this respect, defects are microstructural discontinuities (vacancies, dislocations, surfaces, phase interfaces), but as well solute interstitial (e.g. hydrogen, carbon, nitrogen) and substitutional impurities, and precipitates. Their effects on materials properties are governed by the defects’ interactions among themselves, with the crystal structure and with external fields, such as stress and temperature. Thereby it needs to be considered that the defect structure of materials is not a static state, but it changes dynamically due to the imposed interactions. This changes solubility limits, phase boundaries and the stability of phases in alloys, as well as diffusion mechanisms, the electrical conductivity, hysteresis phenomena of intercalation processes, the mechanical strength and fatigue properties of materials.

We aim for the development of a systematic understanding of process-microstructure-property relationships of materials, and their optimization for applied materials. For this, in a holistic approach we combine in-situ and ex-situ methods of high-resolution material characterization with methods for the determination of macroscopic material characteristics. This enables identification of defects and of their spatial configuration, facilitating the scale-bridging correlation with materials properties.

A main focus of our work lies on the study of structure and state of nano-scale metal-hydrogen model systems (thin films, clusters) and imposed changes of their thermodynamics. These aspects are governed by the sites where hydrogen is dissolved in a metal, how hydrogen absorption changes the microstructure and the mechanical stress state of a metal, and how this affects the physical properties of metal-hydrogen systems. Based on these general considerations we study additive manufactured and nano crystalline bulk materials, materials for hydrogen storage, gas sensors and the hydrogen embrittlement phenomena of steels.

In the frame of the KNMF of the Helmholtz association we cooperate with national and international research groups and support by means of electron microscopic and FIB expertise, especially regarding energy materials, high entropy alloys, magnetic materials, and nano particles. Within the Programme for „Materialien und Technologien für die Energiewende“ (MTET) we are involved in the materials optimization for sustainable technologies.

UHV cathode beam sputter system (Bestec GmbH, base pressure 10-10 mbar) with in-situ STM and in-situ AFM/STM.

Left: Transmission electron microscopy image (dark field) of stacking faults in the Cr2Nb phase of the directional solidified Nb-8.7Si-33.1Cr alloy, creep deformed at 1200°C and 120 MPa (Florian Gang, Mechanical and oxidation properties of eutectic Nb-Si-Cr alloys. Dissertation thesis, Department of Mechanical Engineering, Karlsruhe Institute of Technology, Karlsruhe (2016)). Right: Sample of Dr. Florian Gang (NbSiCr alloy): Transmission electron microscopy image (bright field) of dislocations in the Nb-Si-Cr matrix, that are pinned at Cr2Nb precipitates (unpublished).

Left: Scanning tunnelling microscopy image of hydride precipitates in a 55 nm epitaxial niobium thin film at 4x10-6 mbar hydrogen pressure (Nano Let. 16 (2016) 6207).

Right: Thickness-dependency of the critical temperature of hydride formation in epitaxial niobium-hydrogen thin films (Chem. Phys. Chem. 20 (2019), Int. J. Hydr. En. 41 (2016) 2727).Hydride formation can be suppressed by mechanical constraint conditions. Conversely, relaxation of mechanical stress by plastic deformation changes the defect structure of the metal and the stability of the phases.

Thickness-dependency of mechanical in-plane stress in niobium-hydrogen thin films (Chem. Phys. Chem. 20 (2019) 1890-1904, Appl. Phys. Let. 106 (2015) 243108), measured via inductive in-situ stress measurement.